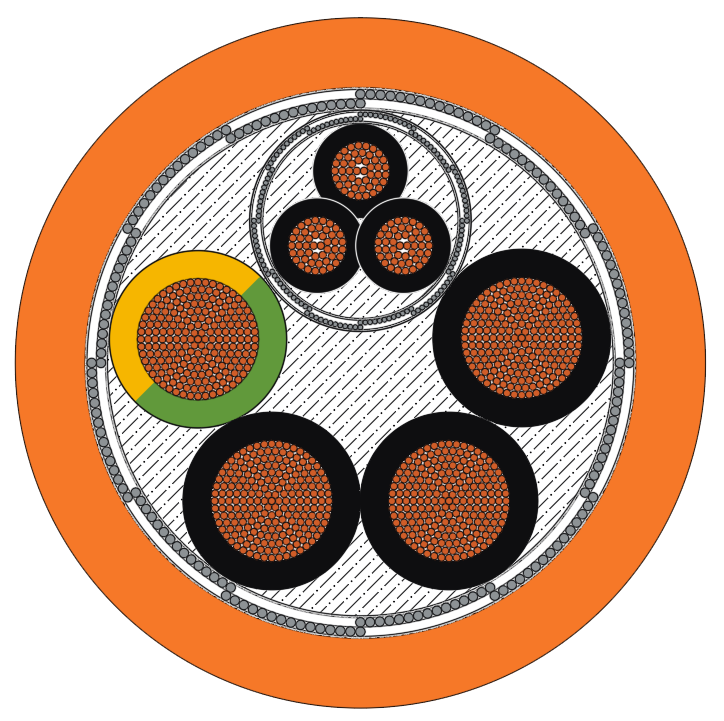

- Spezialkabel

KABELSUCHE

Wählen Sie bitte die Kabeleigenschaften entsprechend Ihren Bedürfnissen aus. Die gefunden Produkte werden angezeigt.

KABEL FÜR DIE MOBILE VERLEGUNG

CE-Kabel und Kabel mit Zulassungen vom Typ UL oder CSA für die Verlegung in Energieführungsketten.

KABEL FÜR DIE FESTINSTALLATION

CE-Kabel und Kabel mit Zulassungen vom Typ UL oder CSA für die Festinstallation.

KABELTYPEN

Suche von Kabeln anhand ihrer Einsatzweise. - KABELDURCHFÜHRUNGEN

- Kataloge

- Spezialkabel

KABELSUCHE

Wählen Sie bitte die Kabeleigenschaften entsprechend Ihren Bedürfnissen aus. Die gefunden Produkte werden angezeigt.

KABEL FÜR DIE MOBILE VERLEGUNG

CE-Kabel und Kabel mit Zulassungen vom Typ UL oder CSA für die Verlegung in Energieführungsketten.

KABEL FÜR DIE FESTINSTALLATION

CE-Kabel und Kabel mit Zulassungen vom Typ UL oder CSA für die Festinstallation.

KABELTYPEN

Suche von Kabeln anhand ihrer Einsatzweise. - KABELDURCHFÜHRUNGEN

- Kataloge

Menü