| Cross section min (mm2) | Cross section max (mm2) | Dynamic Installation | Static installation |

|---|---|---|---|

| 0.14 | 1.50 | Occ. Flexing 10 x Ø | 6.0xØ |

Suitable for static or flexible applications with free movement, without tensile stress and forced motion control in dry, damp, and wet environments; however, not suitable for outdoor use. Used as control and signal cables in the milliampere range for computer systems, control devices, and scales. Due to its extremely small outer diameter, it is especially suitable for sub-miniature plugs and electronic devices. These cables are designed with shielding and a drain wire to minimize electromagnetic interference.

-40 °C +80 °C

Occasional Flexing-5 °C +80 °C

0,14mm² 350 V

≥ 0,25 mm² 500 V (not for power applications)

(C/C)

0,14-0,25 mm² 1200 V (C/C)

0,34-1,50 mm² 2000 V (C/S)

0,14-0,25 mm² 800 V (C/S)

0,34-1,50 mm² 1200 V

> 20 GOhm/cm

~ 78,0 ohm

Inductance 0,65 mH/Km

Mutual capacitance @ 800 Hz (C/C)

0,14-0,25 mm² ~ 100 pF/m

0,34-1,50 mm² ~ 150 pF/m

Mutual capacitance at 800Hz (C/S)

0,14-0,25 mm² ~ 200 pF/m

0,34-1,50 mm² ~ 270 pF/m

Signal conductors |

|

|---|---|

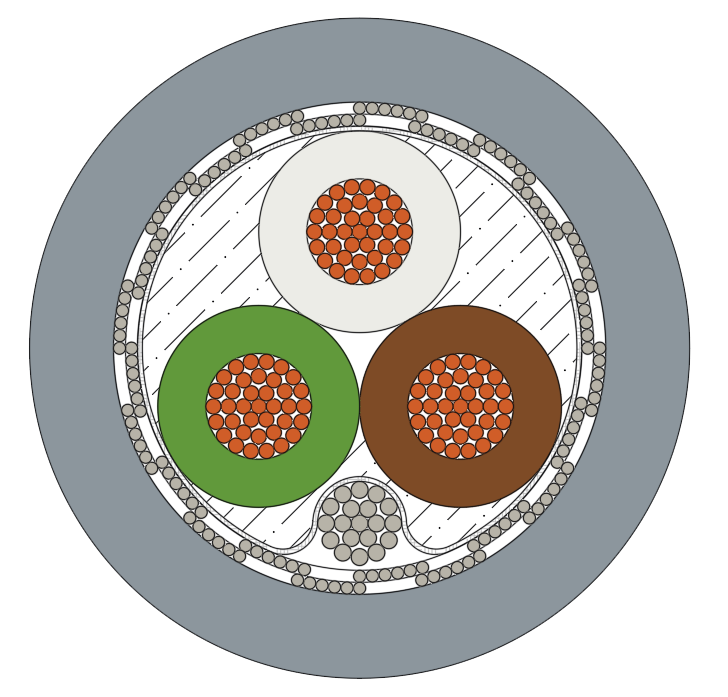

| Conductor | CL5 Flexible. Bare Copper |

| Insulation | PVC compound. |

| Insulation Color | Colours sequence refers to DIN 47100 standard |

Overall Stranding |

|

|---|---|

filler |

Filler Not hygroscopic |

SEPARATION LAYER |

Tape Polyester transparent. |

DRAIN WIRE |

Drain wire Tinned Copper |

screen |

Shield Tinned Copper 85 % ± 5 % |

| Sheath | PVC compound. |

| Sheath Colour | Gray, RAL: 7001, desina: no |

Fire performance

IEC EN 60332-1-2

DIN VDE 0482-332-1-2

Oil performance

EN 50290-2-22

TM54 CEI 20-34/0-1 4 h @ 70 °C oil IRM 902

VDE 0819-102

| TECO code | n° cores x cross-section | cut | rolls (m) | drums (m) | Ext Ø (mm) | Weight (kg/km) |

|---|---|---|---|---|---|---|

21803 |

(1x0,50)ST |

100 |

500 |

3.5 |

40 |

|

8581 |

(2x0,14)ST |

100 |

3.8 |

20 |

||

5797 |

(2x0,25)ST |

100 |

500 |

4.4 |

29.5 |

|

20716 |

(2x0,34)ST |

100 |

500 |

4.7 |

38 |

|

5745 |

(2x0,50)ST |

100 |

500 |

5.4 |

45 |

|

7048 |

(2x1,00)ST |

100/200 |

500 |

6.2 |

65 |

|

11979 |

(3x0,14)ST |

100 |

500 |

4 |

27 |

|

5746 |

(3x0,25)ST |

100 |

500 |

4.6 |

34.5 |

|

11163 |

(3x0,34)ST |

100 |

500 |

5.2 |

44 |

|

7348 |

(3x0,50)ST |

100 |

500 |

5.7 |

55 |

|

5747 |

(4x0,25)ST |

100 |

500 |

5.2 |

43 |

|

11164 |

(4x0,34)ST |

100 |

500 |

5.4 |

51 |

|

5748 |

(4x0,50)ST |

100 |

500 |

6.2 |

61 |

|

10341 |

(4x0,75)ST |

100 |

6.9 |

77 |

||

5749 |

(5x0,14)ST |

100 |

500 |

4.5 |

37 |

|

6717 |

(5x0,25)ST |

100 |

500 |

5.5 |

54.5 |

|

5750 |

(6x0,25)ST |

100 |

500 |

5.9 |

60 |

|

11165 |

(6x0,34)ST |

100 |

6.2 |

61 |

||

7006 |

(6x0,5)ST |

100 |

300 |

7.3 |

89 |

|

5752 |

(8x0,25)ST |

100 |

500 |

6.9 |

86 |

|

13479 |

(8x0,34)ST |

100 |

500 |

7.3 |

80 |

|

11980 |

(10x0,14)ST |

100/200 |

500 |

6.1 |

65 |

|

7439 |

(10x0,25)ST |

100 |

500 |

7.4 |

92 |

|

7047 |

(10x0,50)ST |

500 |

9.2 |

130 |

||

5753 |

(12x0,25)ST |

100 |

500 |

7.6 |

102 |

|

5754 |

(14x0,14)ST |

100 |

500 |

6.6 |

79 |

|

5755 |

(14x0,25)ST |

100 |

500 |

8 |

114 |

|

11981 |

(16x0,14)ST |

100 |

500 |

6.9 |

89 |

|

5756 |

(16x0,25)ST |

100 |

500 |

8.5 |

127 |

|

5757 |

(18x0,50)ST |

500 |

11.1 |

215 |

||

6526 |

(20x0,25)ST |

500 |

9.3 |

155 |

||

5758 |

(25x0,25)ST |

500 |

10.4 |

170 |

||

5759 |

(27x0,14)ST |

100 |

8.5 |

145 |

||

5760 |

(37x0,25)ST |

500 |

11.9 |

230 |