| Cross section min (mm2) | Cross section max (mm2) | Dynamic Installation | Static installation |

|---|---|---|---|

| 0.50 | 16.00 | 7xØ | 4xØ |

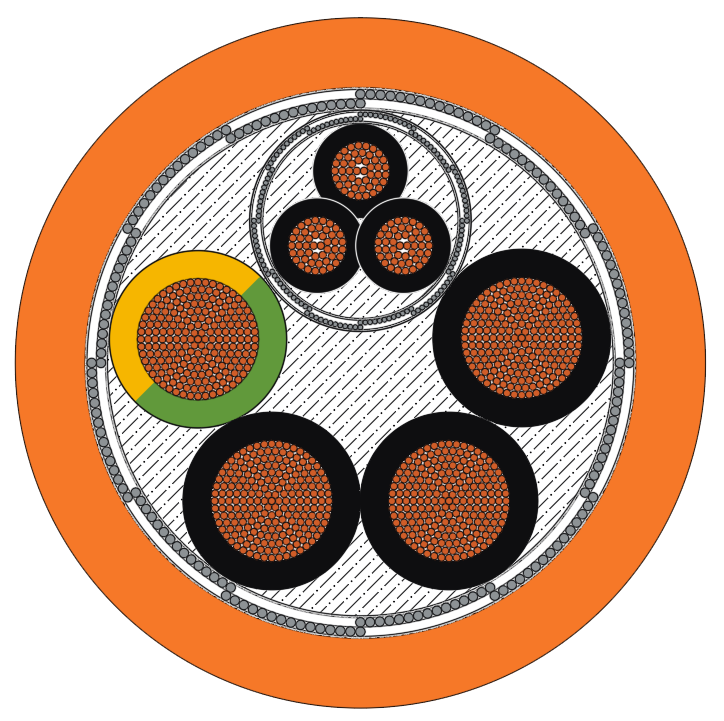

High-performance UL/CSA certified flexible servomotor cables designed for dynamic application in high-speed drag chains, between the motor and frequency converter. The polyurethane outer jacket provides excellent resistance properties against mechanical stress and chemical agents, making these cables suitable for indoor or outdoor use, even in very low temperatures. Screening from electromagnetic interference is achieved thanks to the dense braid shield. These cables have a control triplet of conductors and are compliant with the most commonly used drive system standards.

-50°C +80°C

dynamic-30°C +90°C

static-40°C +90°C

1000 V

4,0 kV

Test Voltage ReferenceEN 50395 part 6-7 - UL/1581

≥1 Gohm/Km (20°C)

≥10 Mohm/Km (90°C)

POWER CONDUCTORS |

|

|---|---|

| Conductor | CL6 Extra-flexible. Bare copper. |

| Insulation | Polypropylene compound (PP) |

| Insulation Color | Black core with white printing ( U/L1/C/L+, V/L2, W/L3/D/L-) + Green-Yellow. |

SEPARATION LAYER |

INNER TAPE POLYESTER TRANSPARENT OR NON-WOVEN TAPE |

Control Triplet Screened |

|

|---|---|

| Conductor | CL6 Extra-flexible. Bare copper. |

| Insulation | Polypropylene compound (PP) |

| Insulation Color | Black core with white printed numbers. |

filler |

Filler Polypropylene |

SEPARATION LAYER |

Intermediate tape Non-woven tape |

screen |

Inner screen Tinned copper 85 % ± 5 % |

SEPARATION LAYER |

Intermediate tape Non-woven tape |

Overall Stranding |

|

|---|---|

filler |

Filler Polypropylene |

SEPARATION LAYER |

Tape Non-woven tape |

screen |

Screen Tinned copper 85 % ± 5 % |

SEPARATION LAYER |

Tape Non-woven tape |

| Sheath | Polyurethane compound (TMPU) |

| Sheath Colour | Orange, RAL: 2003, desina: yes |

Fire performance

Self-extinguishing and flame retardant acc. to DIN VDE 0482-332-1-2, DIN EN 60332-1-2, IEC 60332-1-2, UL 1581 sec.1061 Cable flame

UL VW-1, CSA FT1

Oil performance

VDE 0207-363-10-2, IEC 60811-404 (EU)

CEI EN 50363-10-2, 1581 (UL)

Uv performance

according to ISO 4892-2, EN 50289-4-17, ASTM-D-2565-16, EN 50618

Water performance

UL 1581, IEC 60811-1-3, EN 50396 (Hydrolyses Resistance)

cold Performance

EN60811-1-4

Abrasion performance

ASTM D 4060

Mud performance

Nek TS 606, IEC 60092-360 Annex C+D

Microbe performance

VDE 0282/10

Hozone performance

EN 50396 art. 8.1.3

| TECO code | Oem ref. | n° cores x cross-section | cut | rolls (m) | drums (m) | Ext Ø (mm) | Weight (kg/km) |

|---|---|---|---|---|---|---|---|

43309 |

SEW |

[4G1,50+(3x1,00)ST]ST [4GAWG16+(3xAWG18)ST]ST |

500 |

11.8 |

220 |

||

43310 |

SEW |

[4G2,50+(3x1,00)ST]ST [4GAWG14+(3xAWG18)ST]ST |

500 |

13.4 |

280 |

||

43311 |

SEW |

[4G4,00+(3x1,00)ST]ST [4GAWG12+(3xAWG18)ST]ST |

14.8 |

350 |

|||

43312 |

SEW |

[4G6,00+(3x1,50)ST]ST [4GAWG10+(3xAWG16)ST]ST |

17 |

530 |

|||

43313 |

SEW |

[4G10,00+(3x1,50)ST]ST [4GAWG08+(3xAWG16)ST]ST |

19.8 |

800 |