| Cross section min (mm2) | Cross section max (mm2) | Dynamic Installation | Static installation |

|---|---|---|---|

| 0.50 | 16.00 | 6.0xØ | 4.0xØ |

| 25.00 | 95.00 | 10.0xØ | 4.0xØ |

High-performance UL/CSA certified flexible multicore cables designed for dynamic application in high-speed drag chains, also suitable for permanently flexible applications that allow free movement without tensile stress and without motion control in dry, damp, and wet environments. Reduced diameter and optimized minimum bending radius thanks to the low-capacity material. The polyurethane outer jacket provides excellent resistance properties against mechanical stress and chemical agents, making these cables suitable for indoor or outdoor use, even in very low temperatures. Widely used for high-performance applications such as pumping stations, compressors, generators, and power systems. Screening from electromagnetic interference is achieved thanks to the dense braid shield.

-50°C +80°C

dynamic-30°C +90°

static-40°C +90°C

1000 V (UL/CSA)

uo/U 0,6/1 kV (VDE)

4.0 KV

Test Voltage ReferenceEN 50395 (Part 6-7)

- UL / 1581

≥1 Gohm/Km

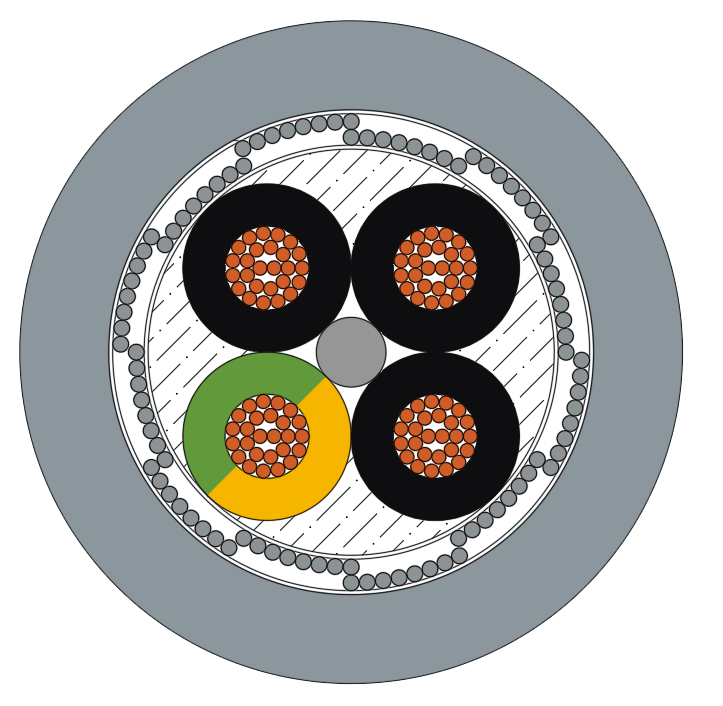

POWER CONDUCTORS |

|

|---|---|

| Conductor | CL6 Extra-flexible. Bare copper. |

| Insulation | Polypropylene compound (PP) |

| Insulation Color | Black core with white printed number + green yellow |

SEPARATION LAYER |

INNER TAPE POLYESTER TRANSPARENT OR NON-WOVEN TAPE |

Overall Stranding |

|

|---|---|

filler |

Filler Polypropylene |

SEPARATION LAYER |

Tape Non-woven tape |

screen |

Screen Tinned copper 85 % ± 5 % |

SEPARATION LAYER |

Tape Non-woven tape |

| Sheath | Polyurethane compound (TMPU) |

| Sheath Colour | Gray, RAL: 7001, desina: no |

Fire performance

Self-extinguishing and flame retardant acc. to DIN VDE 0482-332-1-2, DIN EN 60332-1-2, IEC 60332-1-2, UL cable flame

UL VW-1, CSA FT1.

Oil performance

VDE 0473-811-404, IEC 60811-404 (EU)

EI EN 50363-10-2 (EU)

1581 (UL)

Uv performance

Resistant to UV radiation according to ISO 4892-2, EN 50289-4-17 or ASTM-D-2565-16

Water performance

UL 1581 - IEC 60811-1-3

cold Performance

EN 60811-1-4

Abrasion performance

ASTM D 4060

Mud performance

NEK 606

Microbe performance

VDE 0282/10

Hozone performance

EN 50396 Art. 8.1.3

| TECO code | n° cores x cross-section | cut | rolls (m) | drums (m) | Ext Ø (mm) | Weight (kg/km) |

|---|---|---|---|---|---|---|

46282 |

(2x0,75)ST (2xAWG19)ST |

100 |

500 |

6.3 |

58 |

|

46281 |

(4G0,50)ST (4GAWG21)ST |

500 |

6.7 |

70 |

||

46734 |

(4G0,75)ST (4GAWG19)ST |

100 |

500 |

7.2 |

80 |

|

46266 |

(5G0,75)ST (5GAWG19)ST |

100 |

500 |

7.8 |

100 |

|

46267 |

(5G1,00)ST (5GAWG18)ST |

100 |

500 |

8.3 |

120 |

|

46268 |

(5G1,50)ST (5GAWG16)ST |

500 |

9.8 |

165 |

||

46269 |

(5G2,50)ST (5GAWG14)ST |

500 |

11.2 |

235 |

||

46270 |

(7G0,75)ST (7GAWG19)ST |

500 |

9.2 |

130 |

||

46271 |

(7G1,00)ST (7GAWG18)ST |

500 |

9.8 |

160 |

||

46272 |

(7G1,50)ST (7GAWG16)ST |

500 |

11.5 |

230 |

||

46273 |

(7G2,50)ST (7GAWG14)ST |

13.5 |

340 |

|||

46274 |

(12G1,00)ST (12GAWG18)ST |

500 |

11.8 |

230 |

||

46275 |

(12G1,50)ST (12GAWG16)ST |

13.8 |

320 |

|||

46276 |

(12G2,50)ST (12GAWG14)ST |

16 |

495 |

|||

46277 |

(18G1,00)ST (18GAWG18)ST |

13.4 |

315 |

|||

46278 |

(18G1,50)ST (18GAWG16)ST |

16.3 |

480 |

|||

46279 |

(25G1,00)ST (25GAWG18)ST |

16 |

460 |