When it comes to the application of special cables in the field of systems, with particular attention to the industrial automation sector, some criteria and some fundamental rules to be followed and used have been defined by the pertinent authorities.

From a regulatory point of view, the rated insulation voltage, that is the reference voltage value for which a cable and its internal conductors allow a continuity of operation without anomalies and safely over time, must be equal to or higher than the voltage in the circuit formed by the respective conductors to ensure the safety of people working near the system.

That is, the rated voltage of each circuit must not exceed its rated insulation voltage.

There are 2 fundamental rules to follow in the European/International and North American markets:

IEC/EN 60204-1, which represents the standard to be followed by all manufacturers of machines and industrial automation and provides instructions and recommendations on the electrical equipment of machines, including electrical panels connected to machines, in order to guarantee safety for people and property, consistency of responses to commands and ease of use and maintenance.

NFPA79/CSA C 22.2 no. 210, which establishes the electrical standard for machine safety in the USA and Canada, therefore in the North American market, describing products for wiring equipment such as heavy-duty cables with a higher rated voltage and temperature than cables for common electrical panels.

From a technical point of view, which instead concerns the application, installation and operation of special cables inside systems in general and in the automation sector in particular, it is necessary to distinguish the rated voltage from the test one to evaluate the reliability of a special cable.

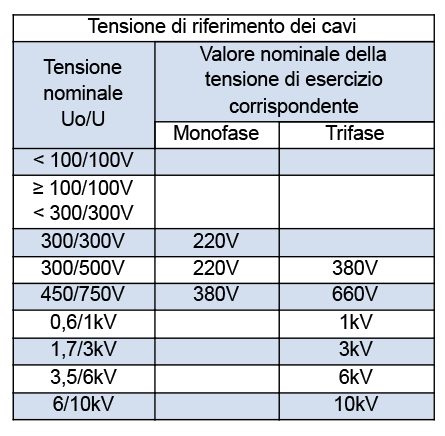

The rated voltage is expressed, at an International/European level, by two values:

Uo: the maximum voltage that the cable insulation can withstand against ground (cable-ground voltage) with safety. That is, it indicates the value of the maximum voltage that the single insulated conductor can support with respect to any conductive object adjacent to it, which is at zero potential. By voltage towards zero potential, we mean a hypothetical shield/armour connected to grounding or any mass of metallic material adjacent to the core.

U: the maximum voltage that the cable insulation can safely withstand with respect to a cable in close contact (conductor-conductor voltage). That is, it indicates the value of the maximum voltage between any two conductors that make up the same cable.

Beyond the European borders, there is no such distinction between Uo and U: the North American standards (ANSI-UL/CSA) indicate a single value to express both parameters. For example: 300V, 600V, 1000V, etc.

The test voltage is much higher than the rated voltage: it is the standardised voltage on the basis of which the capacity and quality of the insulation is checked. A sort of “stress test” to which the cables must be subjected in the testing phase to ensure their reliability and safety.

For example, Te.Co. multi-pole TECNIFLEX® cables for static installation with Uo/U 450/750 working voltage, are tested at 4000V.

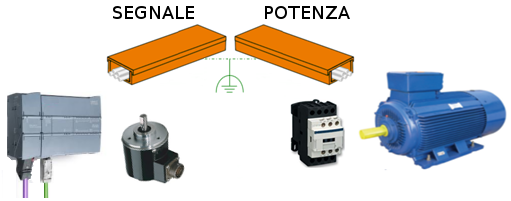

From the point of view of the installation of special cables inside systems in general and of industrial automation, both regulations require that the special cables placed inside the same conduit have a rated operating voltage equal to or higher than the maximum voltage in any of the circuits of that conduit.

For example, if there is a cable that powers a 400V motor and a cable that powers a 120V contactor in a single conduit, the rated voltage of both cables must be equal to or greater than 400V.

Please contact us for more information